Environment segment - waste management overview

Reference boundary

The chapter includes the activities of the waste treatment hub, the waste-to-energy plants and the compost production plants, all in Acea Ambiente.

Once again this year Acea contributed to the pursuit of some of the objectives set by the four Directives of the “Circular Economy Package” of the European Union, in force since 04.07.2018. In particular, at Ecomondo Acea Ambiente presented some projects aimed at enhancing the value of the waste produced, transforming it into a “secondary raw material” to be reused in the industrial production cycle (see the boxes).

Acea at Ecomondo

The 22nd edition of Ecomondo at the Rimini Trade Show took place from 6 to 9 November 2018. The Group participated again this year, taking the event as an opportunity to spread the culture of social and environmental respect and to present some projects of Acea Ambiente and the industrial initiatives related thereto.

In the Acea exhibition space four seminars were held on innovative technologies connected with the recovery of matter and energy from scrap and waste. In particular, the general outline of an industrial project for an innovative plant for the hydrothermal carbonisation of biological sewage sludge was presented, as well as an idea for the treatment of fly ash and, finally, a process aimed at transforming Residual Sodium Products (RSPs), waste with hazardous characteristics, into Secondary Raw Materials (SRMs).

For more information: https://www.gruppo.acea.it/it/gruppo/media-eventi/workshop-acea-ecomondo

Acea Ambiente closely follows the issue of hazardous waste treatment. Such waste is a by-product that presents the greatest problems for disposal, not only in environmental and social terms, but also in economic terms, given the high cost.

At a national level, in fact, there are few treatment facilities and there is a limited availability of space for the final destination in landfills.

Acea Ambiente is exploring the development of processes for the transformation of waste into second raw materials. For example, sodium bicarbonate and calcium chloride dihydrate can be produced from Residual Sodium Products (R.S.P.)

remaining after the waste-to-energy process at the San Vittore del Lazio plant.

Waste that turns in to a second raw material

The project developed by Acea Ambiente allows transforming waste into a second raw material, reusable within the same production process.

Thanks to the technology developed and tested experimentally, it will be possible to convert the salts contained in the Residual Sodium Products (R.S.P.) generated from the neutralisation of the acid component of the combustion fumes of the waste-to-energy plant of San Vittore del Lazio (FR), regenerating sodium bicarbonate and producing pure calcium chloride dihydrate.

The process involves the following operations:

- Leaching, during which all the sodium salts present in high concentrations in the P.S.R. are dissolved;

- Carbonation of the brine thus obtained to transform the sodium into a bicarbonate compound;

- Production of calcium chloride dihydrate in granules for industrial uses.

The residual fraction of hazardous waste resulting from the process and destined for disposal is thus significantly reduced in volume and mass compared to the quantities previously treated, with a consequent reduction in the costs of disposal and supply of sodium bicarbonate.

The carbon dioxide (CO2) necessary for the carbonation phase, several thousand tonnes per year, is drawn from the gas sent into the atmosphere through the flue.

The objectives of the initiative and of the synergistic process undertaken between WA.TRE.CO and Acea Ambiente are the reduction of the quantities of waste to be sent to the landfill, the transformation of the same into a second raw material and the reduction of emissions into the atmosphere, meeting and sharing the principle of sustainable development and the promotion of a circular economy.

Souce: https://www.gruppo.acea.it/it/gruppo/media-eventi/workshop-acea-ecomondo

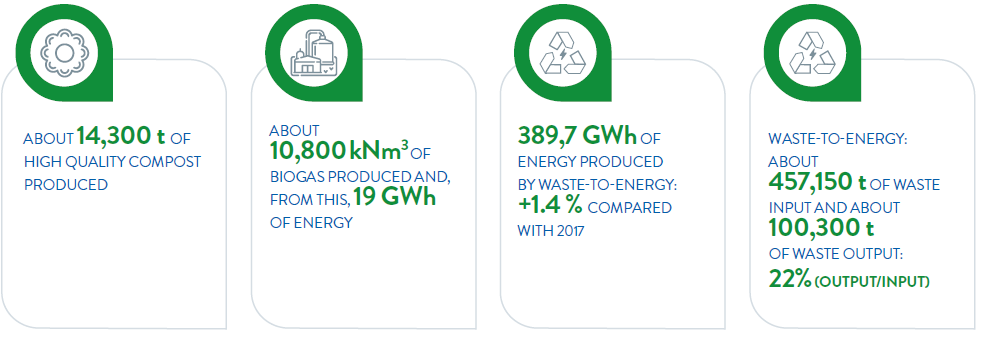

In line with the European vision of the Circular Economy, Acea manages the waste cycle in order to recover, recycle and reuse waste in the best possible way and, when possible, recover energy. The Group, in particular, occupies itself with the following phases of the waste cycle:

- treatment of municipal solid waste (MSW) and other types of waste (like green waste from separate collection, industrial waste, etc.), for the recovery of material and disposal of only the residues in landfills;

- incineration with energy recovery with consequent reduction of the soil needed for disposal;

- production of high quality compost to be directed towards agriculture.

In addition to the above, Aquaser, a subsidiary of Acea, collects and manages the sludge produced by the urban wastewater treatment cycle so that it can be disposed of after any treatment, giving priority to the recovery of material and energy.

The following paragraphs provide further information on the operational aspects of the activities mentioned above. However, these are modern plants, recently revamped, that use advanced technologies necessary to make waste management as efficient as possible.